“If manufacturing companies want to stand firm in a competitive market, they must spare extra money on research and development,” Li said in a statement, according to the official Xinhua News Agency.

China plans to turn hi-tech lab innovations into globally competitive goods

China plans to turn hi-tech lab innovations into globally competitive goods

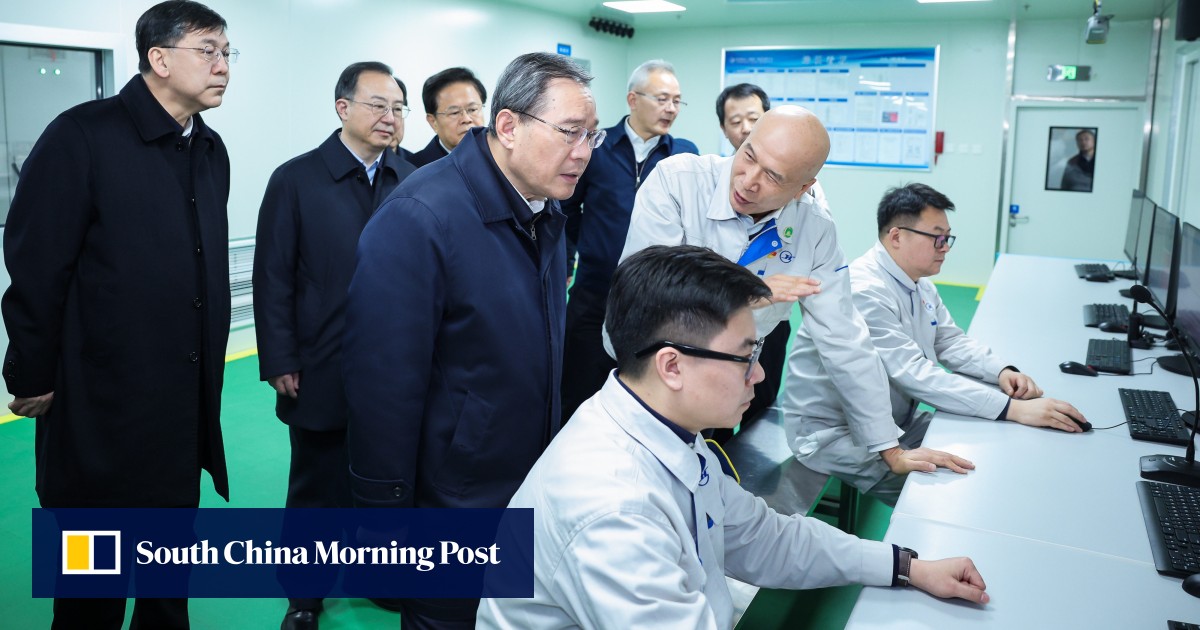

Li visited Shaanxi Fast Auto Drive Group, which is one of the world’s largest suppliers of commercial vehicle transmissions.

We should strive to crack the core bottom technological problems

He asked the manufacturer to embrace the automotive industry’s emerging trends by boosting the integration of digital technologies and green initiatives into their production lines.

“We should strive to crack the core bottom technological problems [in the chips field], and grasp greater market discourse and development initiative,” Li said during a visit to ESWIN Technology Group, which produces semiconductors used in communications and automobiles.

The chip maker, like the other companies Li visited during the two-day trip, is not included on Washington’s so-called entity list, which restricts American tech products, talent and investment flows between China and the US.

The premier also visited Western Superconducting Technologies, which claims to be the world’s only full-process producer of niobium-titanium ingot rods, superconducting wires and magnets, that are widely used in medical MRI imaging and maglev trains.

China needs ‘groundbreaking’ policy changes to embrace disruptive technologies

China needs ‘groundbreaking’ policy changes to embrace disruptive technologies

The company says it is also the only company in China that commercially produces low-temperature superconducting wires.

Li encouraged the former research institute to focus on creating more technologies and continuously improving the transformation and industrialisation of scientific and technological achievements.

China’s manufacturing industry has long faced low investment in research and development (R&D), a gap that is particularly pronounced with the US.

Chinese investment in applied research, mainly driven by enterprises, accounts for about 10 per cent of its total R&D investment, lagging behind 19 to 23 per cent in the US, according to a study by Chinese economist Wu Fuxiang in October.

It will be harder for China to overtake the US in terms of the size of its R&D workforce in the future

“China’s manufacturing R&D investment is seriously insufficient, which leads to a lack of innovation of its manufactures, this has made the gap between China’s manufacturing technology and the US’ to widen further,” said Wu, who is a professor at the School of Business at Nanjing University.

Wu predicted that the size of the US R&D talent pool would be three times the size of China’s by 2025, down from four times as big in 2015. He said the ratio would fall to 2.8 by 2030, but that it would continue to pose a problem for China.

“It will be harder for China to overtake the US in terms of the size of its R&D workforce in the future,” he added.

In the manufacturing sector, the share of medium to hi-tech output in China and the US would stand at 46.02 per cent and 44.54 per cent by 2025, respectively, according to Wu.

“The fading demographic dividend in China and the continuing decreasing labour productivity means that increasing the share of medium- and hi-tech output is an important breakthrough for China’s manufacturing sector to compete globally,” Wu said.