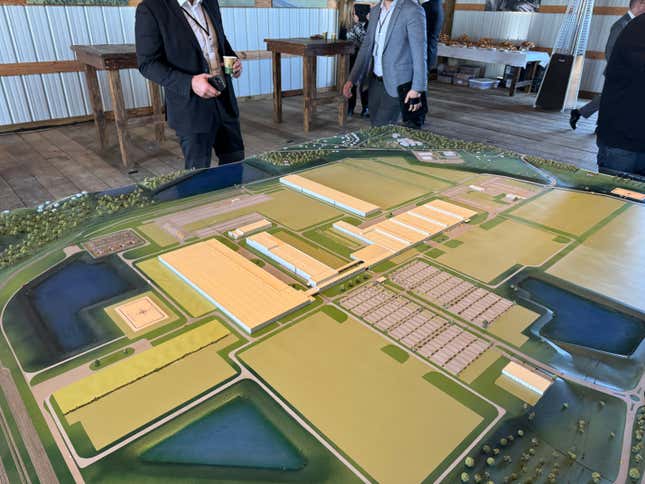

Volkswagen Group made huge waves a few years ago when it announced the revival of the venerated Scout name for a new fully electric truck and SUV that would be built in America. Yesterday I traveled to Blythwood, South Carolina, to witness the groundbreaking of Scout’s new factory, which will be built on a 1,110-acre plot of land and begin production in 2026. After the ceremony, our group of journalists got to sit down at a roundtable with Scout Motors CEO Scott Keogh and head of production Dr. Jan Spies to learn more about the new Scouts, the facility and the company’s philosophy as a whole.

Keogh begins by talking about how the original International Harvester Scout “basically invented the category that became the American SUV,” pointing out that even the Scout name was mimicked by other SUVs that came after. “Scout means to go first — then you had the Explorer, and 4Runner, and Discovery, and Blazer and Trailblazer,” says Keogh, “it’s like the Godfather, it’s the prototype, it’s a great place to start. Even if you’ve never heard of it, ‘Scout’ is a positive thing and has a meaning for itself.”

The new Scouts will ride on a bespoke body-on-frame platform that’s not shared with any other Volkswagen Group products, which Keogh says was the result of a lot of debate. “From a design point of view, it allows you to set the proportions up well aesthetically,” he says, “we want to build something that’s highly robust and highly capable.” Keogh adds that the frame will have a “smart solution for executing the battery concept,” but doesn’t go into any further details. Magna Steyr, the company that manufactures the Mercedes-Benz G-Class, will assist with the Scout’s development. As for whether the platform could be used by other brands in the future, Keogh says there are currently no plans, but the possibility is there.

The Volkswagen Group has 660,000 employees worldwide, but Scout is working like any other startup, with around 350 employees currently. Where being a part of the VW umbrella becomes most beneficial is in the production process. Components will be shared with Scout wherever possible, and having a supply base already in place is a huge boon. Unlike other startups, Scout is able to get better deals in terms of trade and component sourcing thanks to the backing of VW, which will reduce overall costs and help with pace. “As a pure startup, if we wanted to put a plant together, we wouldn’t be where we are at this stage. It’s allowing us to execute a good pace as opposed to always following the prescribed path,” Keogh says. “What are the things that we can take off the shelf and not reinvent the wheel, and what are the things we can differentiate on and make a real difference? We want to press our advantage here.”

But make no mistake, the Scouts’ design, engineering and powertrains will be unique to the brand, and even the factory itself is unlike other VW facilities. “This is not a twin, or brother or daughter to any of the platforms that we’ve ever had,” says Spies, “when I purchase production equipment for Scout, I take technical specification experience, but not components or parts of factories or the assemblies from any other plant. This is a disadvantage in terms of speed, but a huge opportunity to really deliver the cars that have to be unique for the market.”

To that end, it was important that the Scout’s design, platform and specs be created specifically with the American market in mind. The VW Group has a high market share in China and Europe, but its footprint is much smaller in the United States. “Scout allows us to plunge into the two biggest profit pools in America,” Keogh says, explaining that structuring the company as a clean-slate startup is the smart thing to do, as it doesn’t inherit any of the legacy challenges.

According to Keogh, the production Scout’s design is “hyper, hyper, hyper close” to being finished and locked in, and the engineering is “maybe a tack or two behind.” What we’ll see get revealed this summer won’t be a fanciful concept vehicle — Keogh says “we’re not going to be in the business of showing fanciful exploration that’s never going to get made — but there may be a few minor tweaks between the prototype show trucks and the final production vehicles. Most importantly, Keogh promises that “it’ll be awesome.”

The new Scouts are being engineered with the aftermarket already in mind, too. Keogh acknowledges that aftermarket accessories are of huge importance to off-roaders, so Scout is already having conversations with brands to partner with from jump with a factory accessorization program, along with designing its own accessories. “The key thing was to get it all dialed in on the platform, so we have the software and packaging ready for whatever may be coming up,” Keogh explains, avoiding the pitfalls of finishing a car and then trying to make accessories work after the fact.

Keogh goes on to talk about how Scout isn’t trying to position itself in any specific market segment or competitive set. “I view Scout a little bit like Levi’s, if you will,” he says, “Levi’s can be worn at Nobu in Malibu, and it can be worn on a worksite. It’s a cool, iconic American brand.” He calls out the Bronco and Defender as being great examples of “community vehicles” that aren’t just another generic SUV. “We’re not building something to navigate the strip malls of America, we’re building something to navigate America,” Keogh remarks, “it’s going to be a car with character, it’s going to be a car with personality.”

More than anything else, Scout wants to make sure the new trucks are true to the original brand, and that they appeal to owners both past and present. “If the community doesn’t think you’re authentic, and grounded, and real, then you’re a poser. And if you’re a poser, it’s not going to work,” Keogh says. “If you have a mismatch between what the brand was anchored in, and what you’ve put in the marketplace, then that connection is going to be smelled out.”

Both the SUV and truck will be shown at the same time, but they won’t enter production in parallel — Spies says it’s never a good idea to start a factory that way, but they are prepping for a quick ramp-up, so customers won’t have to wait long after the first model goes into production. The brand’s plan currently only includes the truck and SUV, but the factory will be able to handle a variety of packages and derivatives, and Spies adds that “we have the opportunity to build all the ideas that are in the sketchbooks of our designers and marketing people” thanks to the flexibility of the ground-up facility. Eventually the factory will be able to produce more than 200,000 vehicles per year and create 4,000 new jobs. Scout is also working with high schools and colleges in the area to recruit and train students for when the factory is up and running.

There’s still a ton we don’t yet know about the Scouts, and some things the brand itself hasn’t figured out. Keogh says Scout hasn’t decided how the vehicles will be sold, whether it be through dealerships or direct-to-consumer. Scout hasn’t said anything about range or performance targets, how big the vehicles will be or how much they will cost.

It’s obvious that Keogh and the rest of the Scout team are genuinely excited to build the brand and show off what they’ve been working on. “The dream of any brand is to start at day one with some momentum and some love and some community, and I think we’ve worked really hard on that,” Keogh says. “It’s the chance of a lifetime.”