Electric vehicles need batteries, and most batteries are made with lithium, a critical material European automakers are chasing as they face tough competition from China.

Now an Australian firm says it can help, with a refinery in Germany set to extract the sought-after mineral from briny underground water deep below a town near the French border.

Vulcan Energy says its new plant west of Frankfurt, now in its pilot phase, plans to soon produce lithium for batteries used by auto manufacturers including Volkswagen, Renault and Stellantis.

Excess heat from the geothermal water source about two kilometres (over a mile) below the Rhine Valley will help heat homes in a local community, the company says.

The German refinery “is a really important part of Europe’s critical raw material independence,” Vulcan Energy senior executive Francis Wedin told AFP.

For now Europe’s lithium battery sector is struggling to get established just as regional demand for electric vehicles has slowed.

Vulcan Energy hopes it will eventually help boost Europe’s nascent industry producing the silvery, white metal, a key component in the lithium-ion batteries widely used in EVs.

Commercial production is scheduled to start in 2027, with the process subsidised by the German government to the tune of 100 million euros ($106 million).

With the clock ticking towards a 2035 European Union deadline to phase out the sale of new combustion engine vehicles, carmakers are rushing to secure supplies of lithium.

The EU also wants to cut reliance on foreign countries for supplies of minerals vital to the green energy transition — particularly China, which plays a dominant role in mining and refining many raw materials.

There are currently two main methods to extract lithium.

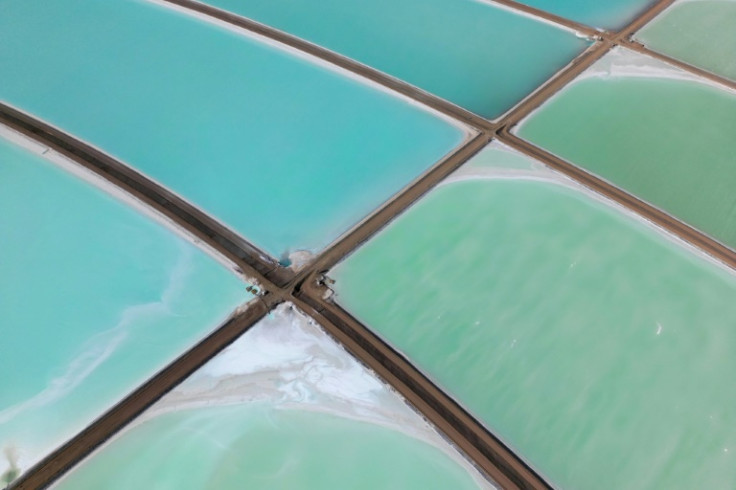

Sixty percent is extracted from rock while the rest comes from the evaporation of brine, or salty water — a technique that uses less energy but is slower and consumes more water.

Vulcan’s approach is similar to the second method, with the brine taken from geothermal reservoirs below the town of Landau, located near the French border.

Using electrolysis and crystallisation, the material is then processed at the Frankfurt plant into lithium hydroxide, the raw material that goes into batteries.

Boosting its green credentials, the firm also says its lithium production process is carbon neutral.

When hot water is pumped up to the surface from the subterranean reservoirs, the heat and energy are then used by the local community.

“Because you have the heat in the subsurface, in the brine, you can produce actually at very low cost” said Wedin. “So we think we can beat China on cost and carbon footprint.”

China is the world’s third largest lithium miner, behind Australia and Chile.

From 2027 the aim is to produce some 24,000 tonnes of lithium hydroxide each year in Frankfurt — enough for half a million car batteries, according to Wedin.

The lion’s share of battery making so far still takes place outside Europe, mostly in China.

To build European capacity, Vulcan is not alone in setting up a lithium refinery in Germany.

Rival AMG Lithium opened its own in the country’s east in September and is targeting annual production of 20,000 tonnes, although it imports its raw materials from Brazil.

The EU is aiming to ensure 40 percent of critical minerals are refined inside the bloc and has taken steps towards this goal.

It signed an agreement with Serbia this year guaranteeing that all lithium extracted in the country will in future be destined only for use in Europe.

A total of 28 extraction or refining projects are in the pipeline in the bloc and, if they successfully begin to operate, would allow Europe to meet half its lithium needs by 2030.

None have yet got past the pilot phase, however, and recent falls in global lithium prices have discouraged investment and led to delays in some projects.

Clean transport advocates warn that ensuring a secure lithium supply is only a small step, with far more to be done before Europe can become independent in battery manufacturing.

“If we want to be truly independent of other countries, every stage in the construction of batteries must take place in Europe,” said Alina Racu, an expert at the NGO Transport & Environment.

AFP

AFP

AFP

AFP

AFP

AFP