Preventing or clearing ice build-up on surfaces is a major winter problem, as areas of the southern US are currently experiencing. Scientists at the Korea Advanced Institute of Science and Technology (KAIST) have now developed a new thin film coating made of gold nanorods that can passively melt ice using just sunlight.

In regions with chilly winters, ice can build up on surfaces and cause all kinds of havoc. Finding ways to keep cars, planes, roads, runways, windows, solar panels, power lines and other infrastructure clear of ice is a major area of engineering research. But salts are hazardous to the environment, and embedding electrodes that heat up surfaces requires energy.

A surface that can passively remove ice could be more efficient and simpler in real-world applications. The KAIST team’s new coating should do just that, capturing sunlight to heat itself up to remove ice.

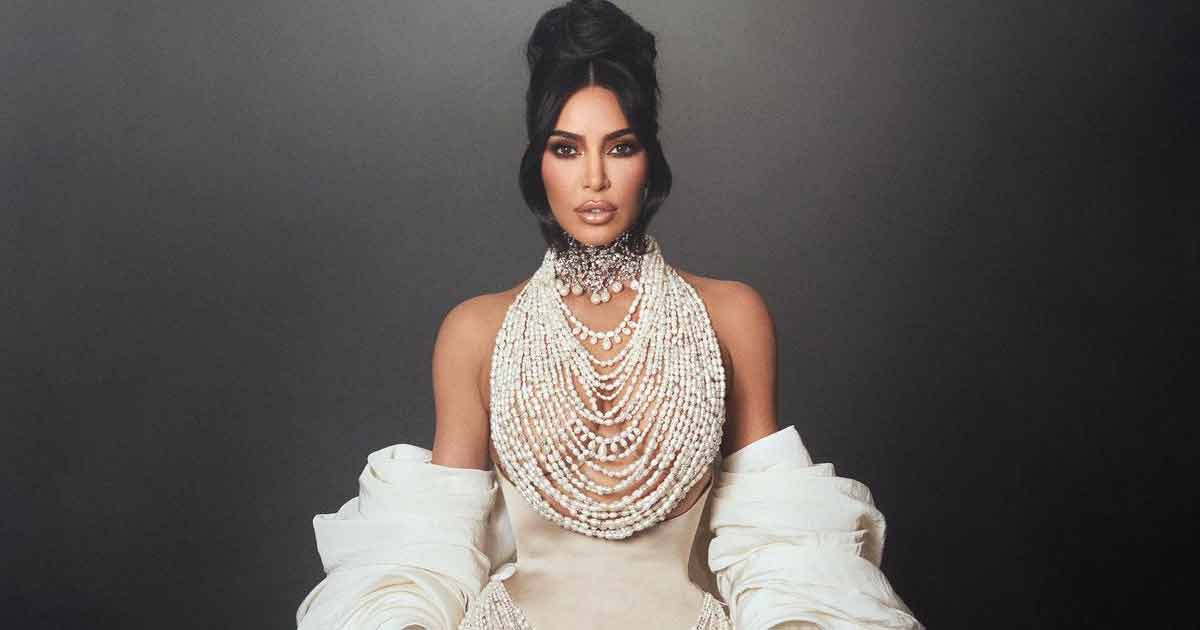

The film is made up of cellulose nanocrystals (CNCs) as a base, which can be easily extracted from natural sources, the team says. The active ingredient though is the golden nanorods, which are the bits that absorb sunlight and heat up. Through a specialized manufacturing technique, the researchers created films where the golden nanorods would arrange themselves into rings, improving their de-icing capabilities.

KAIST

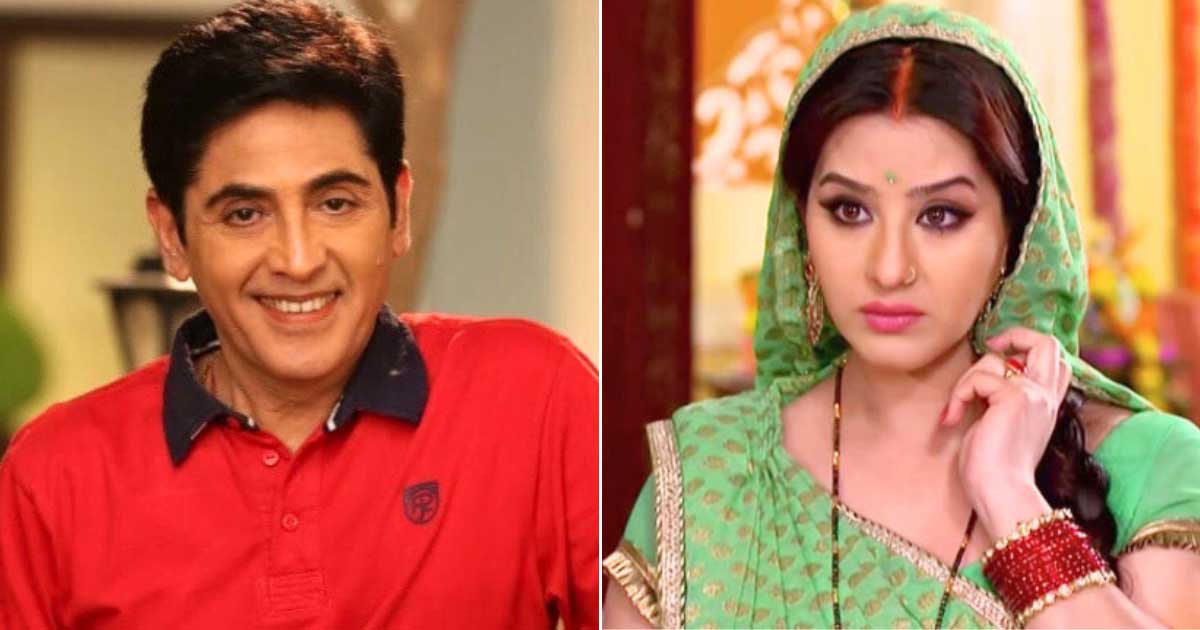

The team tested the material in the lab by placing a temperature control plate on the bottom, and a waterproof layer to the top of the film, and put it to work in anti-icing (preventing frost formation) and de-icing (removing already-built-up ice) scenarios. In both cases, after as little as 10 minutes of light exposure the surface was largely ice-free.

Exactly how well it would work to de-ice thick layers of frost remains an open question – it seems like at least some of the gold nanorods surface needs to be exposed to sunlight for it to heat up. The use of gold, where other similar systems use copper, raises questions of cost and scalability too. That said, there is still more optimization work to be done, the team says, and the manufacturing technique seems to be the main point of difference.

“This technique can be applied to plastic, as well as flexible surfaces,” said Professor hyoungsoo Kim, corresponding author of the study. “By using it on exterior materials and films, it can generate its own heat energy, which would greatly save energy through voluntary thermal energy harvesting across various applications including cars, aircrafts, and windows in residential or commercial spaces, where frosting becomes a serious issue in the winter.”

The research was published in the journal Nature Communications.

Source: KAIST